Maintenance of sewing machine parts is ongoing for the longest possible service life.

Jute stems to dry in the sun before using them as building material.

Waste pieces of rubber are taken care of and being reused.

What is economic sustainability for us?

We believe in circular products. Products made from natural materials, under decent working conditions, which in their timeless design and high quality last much longer. When it’s time for a new carpet, the old one goes on to the children, a friend or second hand. And when the time comes for a trip to the recycling station, we want all our products to be able to be recycled and turned into something else.

Or is it possible to manufacture products that never wear out, that can always be repaired? We’re not quite there, but we’re working on it. Until then, wear our products with a clear conscience. And join us on our circular sustainability journey.

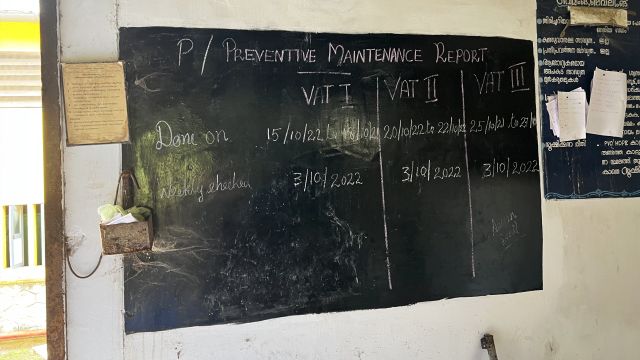

Preventive maintenance of production units.

Waste products

The waste from the production of our rubber mats in India is taken care of and mixed with natural rubber when new mats are produced. This gives higher durability of the product without having to mix in other recycled rubber from e.g. the car industry which often contains a certain amount of metals and other chemicals.

The jute fiber is completely biodegradable

The jute fiber is a biodegradable product, just like most things are eventually, although it is a matter of time. Now a number of producers in southern India have joined forces to find out how long it takes before a jute rug is really composted, i.e. decayed.

The cycle for a test is 180 days and the hope is that that time will be sufficient. Burning jute also works well, but it only produces harmless and useless ash, not coal which in turn could be used for heating. Today, most advocate composting rather than burning, but it is an ongoing process to find a good solution with evidence of how the residual product can best be utilized from a circular economy perspective.

The complete process

Our producer in India has a well developed circular view of what sustainability means. They see the whole process. For them, jute is not a 100% sustainable material as it has to be replanted after harvesting. Coconut fiber, on the other hand, is durable because the palm stands for decades and produces new coconuts after 8-10 months. The same applies to the rubber tree, which constantly emits sap (natural latex) as long as the tree lives.

Water purification

The waste from the water treatment’s first basin consists of 80% jute dust which is separated and compressed into blocks which are then picked up by truck by the authority in Kerala. Together with other producers, a project is underway with a university where they are investigating how the jute waste can generate plant fertilizer. Today, it is known that crops fertilized with the residual product grow and thrive. Now it remains to be seen how vegetables and fruits react and, by extension, the people who eat the crops.

The life of the rubber mat

It is also discussed how to further extend the life of a rubber mat. The product is almost indestructible, but it loses some of its luster over time. So what can be done to maintain the luster? Lubricants such as Vaseline work well for the visual, but not enough because the rubber then attracts dirt instead. Our producer is testing different options and will keep us updated.